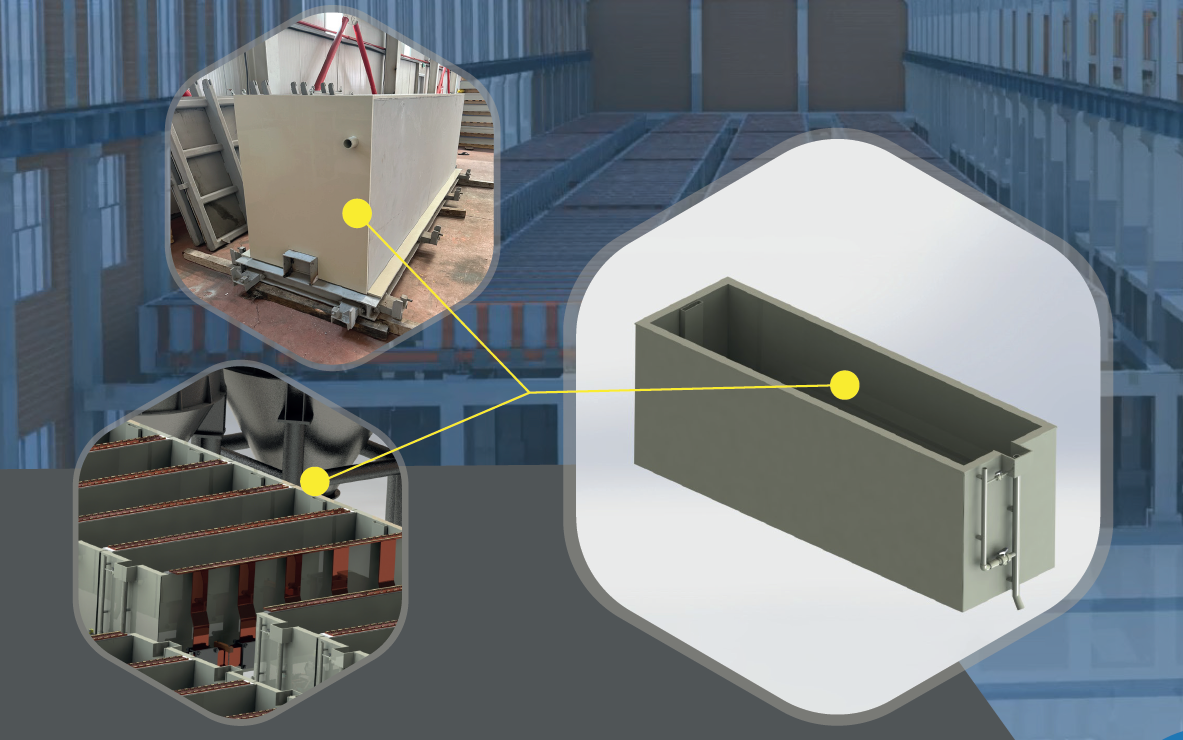

PP (Polypropylene) and HDPE (High Density Polyethylene) tanks are durable and reliable storage solutions widely used in the chemical industry. These tanks offer many advantages in chemical storage, processing and transportation.

Features of PP and HDPE Tanks

- Chemical Resistance: Highly resistant to acids, bases, salt solutions and many organic chemicals. It has a long life thanks to its structure that does not have a risk of corrosion.

- Lightweight and Portable: Since it is lighter than metal tanks, it is easy to carry and install.

- Heat Resistance: PP tanks can generally operate between 0°C and 100°C. HDPE tanks, on the other hand, are durable between -40°C and 80°C.

- Leakage: It provides leakage thanks to its welded or solid designs, allowing chemical substances to be stored safely.

- Economic: It is an economical solution with its low production cost and long service life.

Areas of Usage

- Chemical Storage: Used for safe storage of acids, bases, solvents and various reagents. Allows protection of hazardous substances against environmental effects.

- Mixing and Processing Tanks: Used as tanks where chemical reactions take place or mixtures are prepared. Heating or cooling systems (serpentines) can be integrated.

- Waste Management: A reliable option for the collection and transportation of chemical waste. Prevents hazardous liquids from harming the environment.

- Water Treatment and Chemical Preparation: Suitable for the preparation and storage of chemical solutions in water treatment plants.

Advantages of PP and HDPE Tanks

- Reliability: A durable option for long-term use.

- Flexibility: Can be produced in sizes and features suitable for need.

- Easy Maintenance: Easy to clean and maintain thanks to its smooth surface.

- Environmentally Friendly: Produced from recyclable material and causes minimum harm to the environment.